Harrington & Richardson Model 922 BruceVarner.com

Harrington & Richardson Model 922 (Pre-1940)

4th Variation (Birds Head)

Internal Function (Final Page)

--.22 Caliber, 9 Shot Revolver--

If you have not been to page 1 of this article, please click here. This is the final page of the information on the interaction and functioning of the Harrington & Richardson early (pre-1940) Model 922 4th variation revolver.

This pistol presented itself with several issues. It had been neglected for many years. Apparently kept in a humid environment, inside a leather holster. The metal was rusted and pitted in many places. Someone had it apart in the past and the friction pin was not even in the gun. There was no grip or grip screw. Mechanically, the cylinder turned freely. The cylinder rod looked like someone had beat it with a hammer. The revolver would not cock into single action. Timing was off. The hammer would fall slightly before the cylinder aligned with the barrel. I wanted to ensure that the pistol could be repaired before spending much time "conserving" the revolver. Here are the steps that I followed.

I performed

the following steps:

1) Disassembled

2) Cleaned / soaked

and did some light hand carding of the metal surfaces

3)

Straightened the cylinder pin

4) Machined the slave pins &

studied exactly how the pistol functions

5) Spent time not

believing that the cylinder stop/lock was not designed to really

prevent the cylinder from turning both direction when engaged

6) Purchased a repo single piece grip & adapted a screw to hold

the grip. Learned that the grip screw also holds tension

on the flat main spring

7) 1st reassembly:

-- Gun would

cock into single action but would not reliably hold

-- Timing

off. Lifter (Hand) worn

-- Simple action of setting the

gun down or just touching the cylinder can throw the cylinder

out of alignment with the barrel

8) Disassembled

9) Light Stoning of sear/hammer

engagment point (Ensure correct angle + enlarge notch in in

hammer to hold full cock)

10) Light polish of firing

mechanism pivot points

11) Slight peen of hand (lifter) tip to

the right

12) 2nd reassembly:

--- Single action / hammer

cocked on functioning correctly

--- Action smoother

---

Timing now correct

--- Cylinder rod still difficult to remove

--- Appeared shootable

Conservation Steps:

13) Disassemble

14)

Additional straightening & slight filing/smoothing of cylinder

pin

15)

Placed all metal parts into boiling water for 1 hour, then blow

dry (Rust turns to ferric oxide / black)

16) Card revolver,

parts, crevaces by carding + #0000 steel wool in tight areas (Removes carbon &

gunk)

17) Soak in karosene overnight

(Remove/displace all water) Dry

18) Oil

19) 3rd reassembly:

--- Testing

Here is the conserved and repaired revolver. The revolver

is not restored. Conservation involves bringing back any

existing bluing and removing rust only. Any pits and wear

remain. This type of conservation is less likely to

affect value of an old firearm. As you can see this

revolver is not of display quality. Deep pitting remains.

Howevever, considering the previous condition it is now an

acceptable shooter.

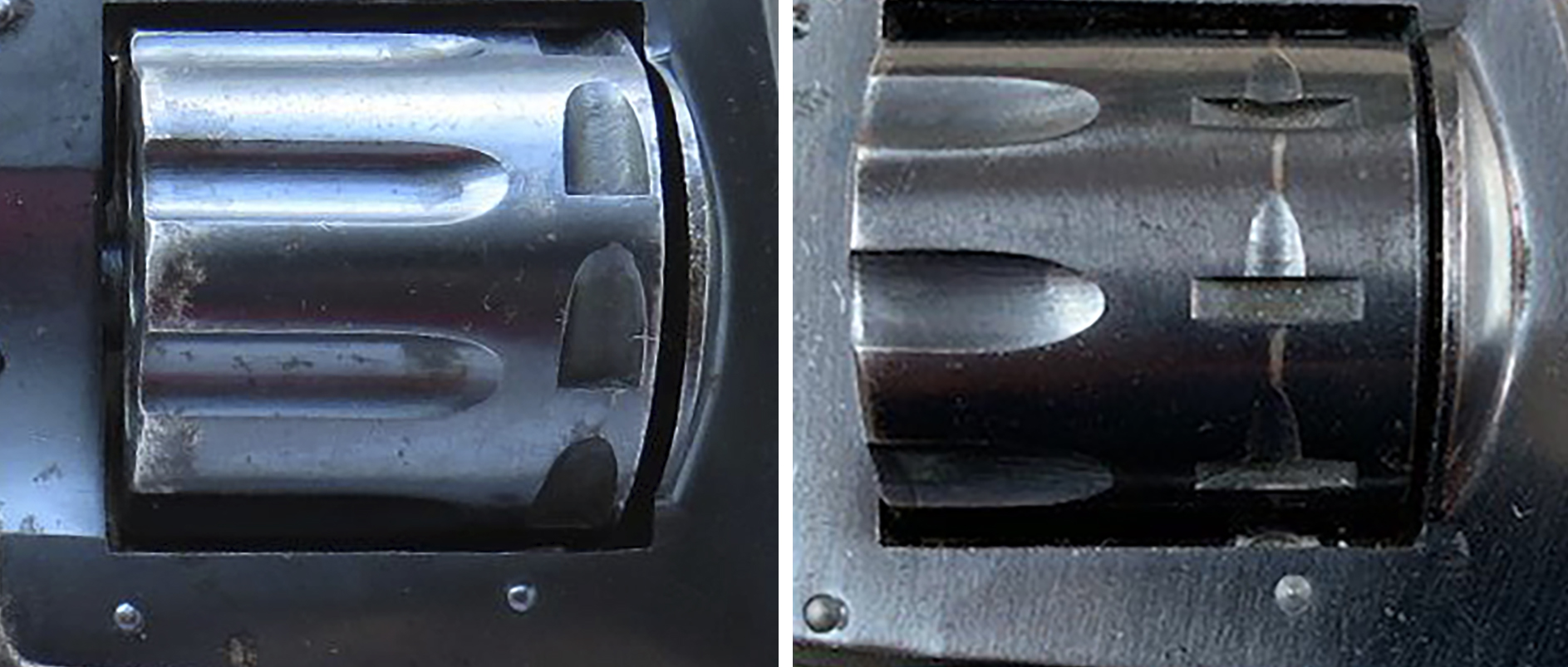

Image #10

Here are two images of different pistols. Left is a

free turning cylinders early model (Like the one in this article).

Right is a later model with 2-way cylinder stop machining.

The left design only stops cylinder from

over-rotating. The right design stops cylinder travel either

way when engaged. On left the cylinder stop is part of the

trigger. Therefore it only engages the cylinder just prior to

a complete pull of the trigger or when the hammer is cocked into

single action. On right the cylinder stop is a seperate part

and engages the cylinder all the time except when the trigger or

hammer begins to be pulled.

Back to Page 1 of Harrington &

Richardson Model 922 (Pre-1940) Revolver

Back to Page

2 of Harrington &

Richardson Model 922 (Pre-1940) Revolver

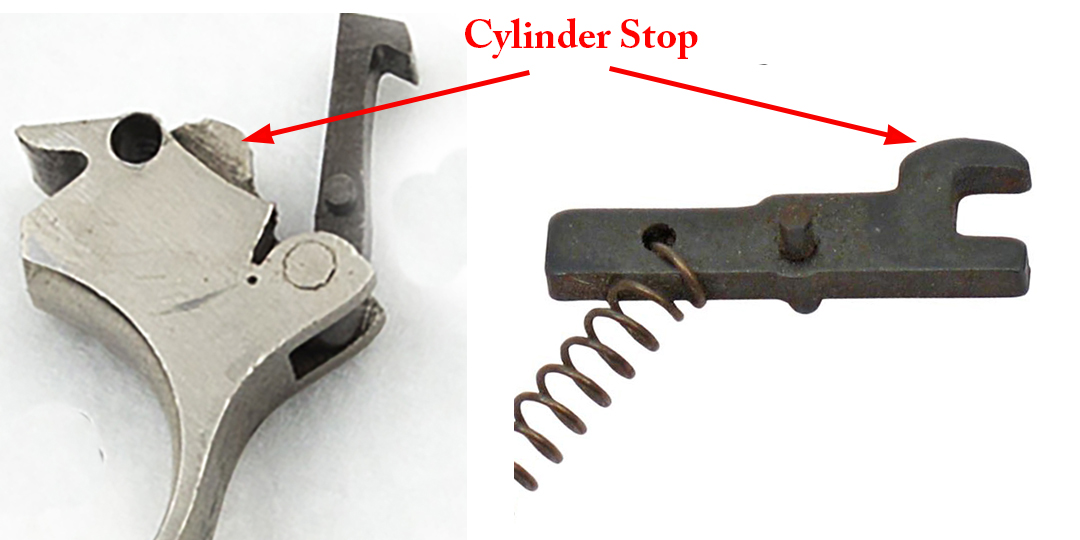

Image #11

(Free Turning Cylinder-Left, Locked Cylinder-Right)

Image #12 (Part of trigger-left, seperate

part-right)